Wire Mesh Cable Tray - Galvanized or Powder Coated Surfaces

Wire mesh cable tray supplies a point-to-point pathway for cables. Made of high quality steel wire and welded into 2" × 4" rectangular grid pattern. the grid is formed into U shaped channels, which supports and carry cables. The hole pattern design make it possible for the cables to pass through and go up and down.

Compared with fiberglass cable trays, the wire mesh cable tray has higher tensile strength and mechanical strength. The material of wire mesh cable trays are various, including carbon steel with various surface furnish and stainless steel. Different surface finish can suit different applications, you can refer to the below chart and choose the perfect one you need.

| Surface finish | Suit material | Standard | Thickness |

|---|---|---|---|

| Pre-galvanized | Carbon steel | ASTM-A6553 | |

| Electric galvanized | Carbon steel | EN 12329-2000 | Minimum 8 microns and average is 12 microns |

| Hot dipped galvanized | Carbon steel | EN 1461-1999 | Above 60 microns |

| Powder coated | Carbon steel | EN: 10309-1999 | Above 50 microns |

| Pickled | Stainless steel | / | / |

| passivated | Stainless steel | / | / |

| Electrolytic polishing | Stainless steel | / | / |

WMCT-01: Stainless steel wire mesh cable tray.

WMCT-02: Powder coated surface wire mesh cable tray.

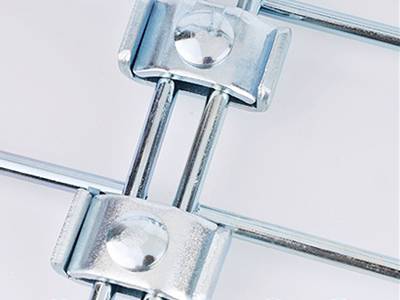

We can not only supply the wire mesh cable trays, we can also supply all kinds of wire mesh cable tray accessories for easy and fast installation. The main accessories are including connection system, supporting system and installation system. Different accessories can be used in different positions for different functions. These accessories can ensure the wire mesh cable tray solid, firm and high strength.

WMCT-03: Wire mesh cable tray supporting accessory.

WMCT-04: Wire mesh cable tray connection accessory.

Specifications of wire mesh cable tray

- Material: carbon steel, SS 304, SS 316L.

- Surface finish:

- PG: pre-galvanized zinc material according to ASTM-A6553.

- EZ: electric galvanized plated according to EN 12329-2000. Thickness average 12 microns, minimum 8 microns.

- HDG: hot dipped galvanized according to EN 1461-1999. Thickness above 60 microns.

- PC: powder coated according to EN: 10309-1999. Thickness above 50 microns, color is optional.

- SS: pickled & passivated, or electrolytic polishing for stainless steel material.

- DC/GT: dacromet/ geomet for accessories.

- Mesh size: 50 mm × 100 mm.

- Wire diameter: 4.0 mm - 6.0 mm. 5.0 mm is the standard and commonly used.

- Length: commonly is 3 m.

- Width: 50 mm, 100 mm, 150 mm, 200 mm, 300 mm, 400 mm, 450 mm, 500 mm, 600 mm.

- Height: 50 mm, 100 mm, 150 mm and special can be customized.

Specifications of WMCT50 wire mesh cable tray

WMCT50 wire mesh cable tray

| Item | Height (mm) |

Width (mm) |

Length (mm) |

Diameter (mm) |

|---|---|---|---|---|

| WMCT50-01 | 50 | 50 | 3000 | 5 |

| WMCT50-02 | 50 | 100 | 3000 | 5 |

| WMCT50-03 | 50 | 150 | 3000 | 5 |

| WMCT50-04 | 50 | 200 | 3000 | 5 |

| WMCT50-05 | 50 | 300 | 3000 | 5 |

| WMCT50-06 | 50 | 400 | 3000 | 5 |

| WMCT50-07 | 50 | 450 | 3000 | 5 |

| WMCT50-08 | 50 | 500 | 3000 | 5 |

| WMCT50-09 | 50 | 600 | 3000 | 5 |

Specifications of WMCT100 wire mesh cable tray

WMCT100 wire mesh cable tray

| Item | Height (mm) |

Width (mm) |

Length (mm) |

Diameter (mm) |

|---|---|---|---|---|

| WMCT100-01 | 100 | 100 | 3000 | 5 |

| WMCT100-02 | 100 | 150 | 3000 | 5 |

| WMCT100-03 | 100 | 200 | 3000 | 5 |

| WMCT100-04 | 100 | 300 | 3000 | 5 |

| WMCT100-05 | 100 | 400 | 3000 | 5 |

| WMCT100-06 | 100 | 450 | 3000 | 5 |

| WMCT100-07 | 100 | 500 | 3000 | 5 |

| WMCT100-08 | 100 | 600 | 3000 | 5 |

Specifications of WMCT150 wire mesh cable tray

WMCT150 wire mesh cable tray

| Item | Height (mm) |

Width (mm) |

Length (mm) |

Diameter (mm) |

|---|---|---|---|---|

| WMCT150-01 | 150 | 150 | 3000 | 5 |

| WMCT150-02 | 150 | 200 | 3000 | 5 |

| WMCT150-03 | 150 | 300 | 3000 | 5 |

| WMCT150-04 | 150 | 400 | 3000 | 5 |

| WMCT150-05 | 150 | 450 | 3000 | 5 |

| WMCT150-06 | 150 | 500 | 3000 | 5 |

| WMCT150-07 | 150 | 600 | 3000 | 5 |

Features of wire mesh cable tray

- Easy installation. We can supply all kinds of accessories, including different angle connections to let the installation easy and fast.

- Good appearance. Stainless steel and galvanized wire mesh cable tray supply bright metal color and PVC coated cable tray can supply various color to suit different applications.

- Save space. It can save 25% space than cable ladder.

- Flexible and permeable. The hole pattern design supply maximum flexible and permeable to the cables.

- Trough style design. This design can keep cables in position.

- Various height. Different height for choice to suit different cable sizes.

- Light weight. The weight of wire mesh cable tray is 30% to 60% less than the traditional cable trays.

- High load capacity. It can load large quantity and heavy duty cables.

- High temperature resistance. The wire mesh cable tray can maintain good conditions even in the high temperature environments.

- Chemical stability. The stainless steel material and hot dipped galvanized material can be used in acid and alkali environments and other harsh environments.

Applications of wire mesh cable tray

Wire mesh cable tray is widely used in all kinds of industries to load cables, the main applications are as follows:

- Low voltage.

- Telecommunications.

- Food industry.

- Beverage industry.

- Data center.

- Fiber optic cables supported on short spans.

Contact us immediately if you are interested in any of our products or you have any questions.

Contact us